PowerView® Reimagined: How SEACOMP and Hunter Douglas built smart shades

Our partnership with the industry leader in window treatments helped elevate one of their premium connected-home products.

Building a Smarter Shade

In 2019, the product development team at Hunter Douglas found themselves in need of an experienced electronics design and manufacturing partner to help bring an upgraded version of their PowerView® product to market.

Prior to the PowerView® project, SEACOMP provided Hunter Douglas with standard power supplies for another product. Because of our existing positive working relationship, Hunter Douglas approached us to help get the new and improved PowerView® product built.

Scott Stephenson, Director of Product for Hunter Douglas, knew they’d be successful if they could find a collaborative partner. “We definitely look for partners that we feel like—and I guess it's a little trite, but are going to be partners. This isn't just a, ‘Okay here's something we'll throw it over the wall to you, and we're going to expect you to throw it over the wall back to us.’ That's not the way we work. We're definitely a company that likes to get our hands in things. We definitely like working with companies that understand that, and have the flexibility to deal with that, and that have proven that they can deliver good, strong solutions at a market-appropriate price point.”

About SEACOMP

SEACOMP is an electronics design and manufacturing services provider. Additionally, our two brands, Displaytech and HDP Power, support your component needs through embedded LCD displays and AC DC power supplies.

We help innovators deliver awesome products and find happiness in the making.

"We’re definitely a company that likes to get our hands in things. We definitely like working with companies that understand that."

- Scott Stephenson, Director of Product for Hunter Douglas

The PowerView® Challenge

Hunter Douglas’s PowerView® is an award-winning motorized smart shade product that brings added convenience, privacy, energy efficiency, and security to the homes of its customers. These smart shades can be controlled by an app, through voice command, or by a remote control unit.

Motorized shades need a power source, and Hunter Douglas’s goal was to ensure that whatever solution powered the smart shades was as elegant, convenient, and user-friendly as the overall product.

Other solutions had various shortcomings: shades could be hardwired into the building, but most product installations were part of upgrades to existing homes versus being factored into new construction. Shades could be designed with built-in rechargeable batteries, but then they would need to be plugged into an outlet, resulting in unsightly dangling cords (if there was even an outlet nearby).

Smart shade users previously relied on non-rechargeable battery packs to power the shades, and batteries had to be changed out multiple times per year depending on usage. This resulted in too much environmentally unfriendly waste and could quickly become a hassle for the user, especially if they had numerous shades installed, each with its own battery pack.

Drilling Into Inspiration

Hunter Douglas’s product development department found inspiration in another household item: a cordless electric drill. Like smart shades, battery-operated drills use short, intermittent bursts of power and become unusable (and inconvenient) if that power runs out. The solution, then, could be similar.

When your drill battery runs low, you don’t have to plug it in or wait for it to charge; you simply swap out your depleted battery for a fully charged one. They wanted to create this same convenient experience for their PowerView® customers.

Product Design Requirements

Hunter Douglas came to SEACOMP with a detailed vision for their product, and we helped them realize it.

The timeline was tight—they wanted to bring the product to market within 12 months.

We also had to help them meet specific cost targets to ensure the price point made sense for the market.

The PowerView® power supply solution would have three components:

-

- Battery

- Wand

- Charging unit

“We looked to SEACOMP to really be very much a turnkey provider for us on this. We came to them with an industrial design that we wanted to meet, but we really looked to SEACOMP to help us figure out the right battery technology and the right charging technology in both pieces of this solution, both of which were extremely important to making the overall solution work well.”

– Scott Stephenson, Director of Product for Hunter Douglas

The Battery

SEACOMP was responsible for battery cell selection and circuitry design. Cell selection is the foundation of the entire product’s design—the cell(s) you select dictate what’s possible for everything built on top.

One critical consideration was the environment the cells would be operating in. The battery pack would be mounted on the back of the smart shade units, so they would be exposed to direct sunlight for extended periods of time. This meant they needed to be able to operate in relatively high temperatures.

The battery also needed to provide power to the smart shades for a long period of time so that users wouldn’t have to swap them very often. However, they also couldn’t be excessively bulky, or they would negatively impact the aesthetic of the product.

The Wand

The wand component would be the physical enclosure for the battery and would need to be mounted on the smart shades and then inserted into the charging unit. It had to have the look and feel of a premium product, and it needed to be easy to swap out. Hunter Douglas wisely didn’t want users to have to deal with screws or complicated latch systems—they’re very easy to break—so they requested a magnetic mount design, which introduced more complexity to the overall product design.

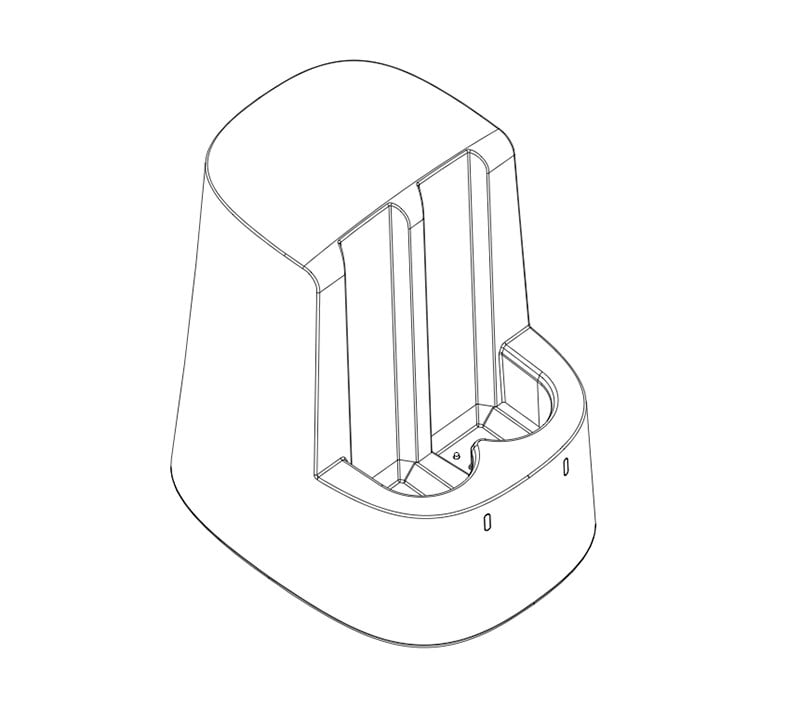

The Charging Unit

Like the wand, the charging unit would be visible in users’ homes, so it needed to have a premium look and feel. It also had to be compact, so that it wouldn’t take up too much counter or shelf space. This meant it had to have a vertical design, even though the wands are mounted on the shades horizontally.

Hunter Douglas’s product team also didn’t want an external power supply. Choosing an embedded power supply added even more complexity; the charging unit needed to have a tight form factor, but still have enough room for the power supply. That had to be balanced with the requirement that it provide fast charging, necessitating a robust (and sizeable) power supply that needed extra space for heat dissipation.

Finally, although they wanted to avoid building a bulky charging unit, it also couldn’t be too lightweight. A unit that’s too light doesn’t feel premium. Plus, they wanted users to be able to easily pull the wands out of the charging unit, meaning the base needed to stay in place.

A Bright Solution

Finding a solution to all of these challenges and hitting an aggressive timeline and cost targets would have been impossible without a tightly integrated team of product designers, engineers, and manufacturing experts. Our team was up to the challenge. We deployed our proven new product introduction (NPI) process to get this project moving.

SEACOMP’s NPI PROCESS

New product introduction (NPI) covers all aspects of defining, developing, manufacturing, and distributing a new or improved electronic product. Our team has refined and optimized this process over the course of 30 years of successfully bringing electronic products to market.

- Roadmap Creation

- Engineering, Prototyping, & Design for Manufacturing

- Production Preparation

- Scaling to Volume Production

- Production Process Optimization

- Logistics & Distribution Support

Getting the Team Together

SEACOMP worked closely with the Hunter Douglas product team throughout every stage of the project. We also collaborated with an external design agency that was tasked with the industrial design, while SEACOMP was responsible for mechanical and electrical design.

We appointed project managers in both the U.S. and China to the project. Our U.S. project manager ensured that project requirements and timelines stayed on track, while our project manager in China followed through on the NPI and production requirements. Our China project manager was able to meet with the Hunter Douglas product team when they visited our production facility in Southeast China.

Spoiler Alert!

SEACOMP’s complete vertical integration, tight-knit team, and proven processes ensured that the PowerView® product reached the market on time and on budget. We prevented any delays in scaling production or securing certifications, and helped bring a product to market that fit the Hunter Douglas brand, ensuring premium, reliable performance.

Here’s how we did it, piece by piece.

Design: The Battery

Cell selection and circuit design were the first steps in the overall mechanical and electrical design of the product. Typical lithium battery cells are rated to perform in temperatures up to 60℃/140℉ for discharging operations, but we selected cells that could perform in temperatures up to 80℃/176℉ to be absolutely certain that they would never fail due to excessive heat.

The battery assembly was made up of four connected cells and a circuit board. Certification and validation testing was required for the individual cells, the connected cells, and the circuit board—in other words, three layers of making sure we got it right.

As we moved to circuitry design, we kept a number of critical requirements in mind: the battery could never overheat, no cell could be discharged beyond the bounds of another cell, energy output had to be balanced, and the battery life needed to be optimized by carefully controlling charge and discharge operations.

During this iterative design process, the size of the circuit board in the battery assembly was increased to improve pogo pin alignment. Further design modifications were made to ensure that the larger circuit board would not rattle once encased in the wand.

Design: The Wand

The magnet connectivity element had to be carefully designed to ensure that the thickness of the wand material was appropriate for the magnet's Gauss value—too thick, and the magnet would not be strong enough to support the wand on the back of the blind.

We also needed to ensure that the magnet could be tightly sealed within the wand unit and would not rattle, which we achieved with a combination of adhesive and ultrasonic welding.

Our mechanical design addressed a number of usability considerations. For example, since the wands sit vertically in the charging unit to help save space, the design was slightly altered to ensure the wands would go into the unit tightly and provide tactile feedback to confirm they’re locked in place.

The plastic molding for the wand unit was done in-house, and then the battery assembly was inserted and tested to ensure that it was charged to the right voltage. Then, ultrasonic welding was completed and pogo pin alignment was tested using a specialized camera. Next, the battery was tested again to ensure no damage was done during welding. Finally, the unit was laser-printed with serial numbers and certifications.

Design: The Charging Unit

The most challenging aspect of the product design process was getting the charging unit right. It needed a robust embedded power supply, a tight form factor, a premium look and feel, and had to vertically charge a battery assembly that was designed to be mounted horizontally.

During the design process, our team detected some LED light bleed in early prototypes, so we recommended that the external material used to build the charging unit be replaced. Later prototypes (and the finished product) were built using a material with better light-blocking properties.

The unique shape and style of the charging unit also presented some initial challenges around getting components off the tool. In early prototypes, after a few shots, parts would end up sticking. We quickly corrected this by changing some draft angles and ensuring the tool was well-polished, making it easier to eject parts.

We also added a zinc-plated iron weight to the charger base to provide additional weight, supporting improved usability and adding to the product’s premium feel. Both the charger and the wand have a high-gloss finish for added visual appeal.

Certified for Success

The PowerView® battery assembly and charger had specific safety certification requirements that needed to be met, but Hunter Douglas’s product team wanted to go above and beyond: they requested that the wand component be UL-listed as well.

SEACOMP ensured that UL and IEC safety standards were met throughout the cell selection and product design process. Any delay in certification would have derailed the project, preventing both teams from hitting their 12-month goal.

“[SEACOMP] brought something to the table which was important to us… the regulatory expertise side of it. We knew that the charger had to be UL approved. We could have gotten away with just having the internal battery pack that was in the rechargeable wand as a UL-registered component, but we wanted to go beyond that. We wanted the whole battery wand itself to be UL-listed and [SEACOMP] brought a lot of expertise to the table and experience… to make that happen and make it happen in a fairly expedient way.”

- Scott Stephenson, Director of Product for Hunter Douglas

SEACOMP’S Certifications

The products we design and manufacture need to meet high standards. Beyond standard safety and compliance certifications, we go the extra mile to help our customers’ products excel in quality and reliability.

ISO 9001:2015

UL SAFETY

CERTIFIED

ISO 13485:2016

Success in the Making

SEACOMP and Hunter Douglas were successful at getting the new PowerView® product to market within 12 months of project kickoff without exceeding target costs.

Since then, over a million units have been shipped with zero defects.

“The communication was great, from a project management standpoint, [SEACOMP] were always really on top of things, letting us know what was going on. I think it was a very open line of communication to really everybody within the SEACOMP organization that we interacted with. We had regular project meetings. At one point during the project as things were getting to crunch time I think it was twice a week, even…it was a very collaborative relationship which I think worked well.”

- Scott Stephenson, Director of Product for Hunter Douglas

“The success of the project was really due to our frequent in person meetings that led us to act as one, cohesive team. The energy, working side by side, with one goal in mind, made the project a fun experience. We’re happy to continue to support Hunter Douglas as their products evolve.”

- Mike Szymanski, CEO at SEACOMP

Watch the Full Interview

For more information about our collaboration with Hunter Douglas, watch this episode of our Innovator Interview series led by Terry Arbaugh, VP of Sales and Marketing at SEACOMP.